What Type of Load Cells Are Used in Tank Weighing System?

A tank weighing system is a tool designed to measure the weight of large industrial containers like tanks and silos. They play a major role in industries where precise measurements of liquids or bulk materials are essential. Whether it’s monitoring inventory levels or ensuring accurate dosing, these systems rely on a key component known as load cells. In this blog post, you will learn the basics of tank weighing machines and explore the types of load cells used in these systems.

Understanding the Role of Load Cells in a Tank Weighing System

These weighing systems use advanced technology to handle the challenges of weighing large containers. They come in different types to fit various tank sizes, weights, and installation needs. Tank scales can be placed above the ground, hung from a structure, or integrated into the tank’s support system.

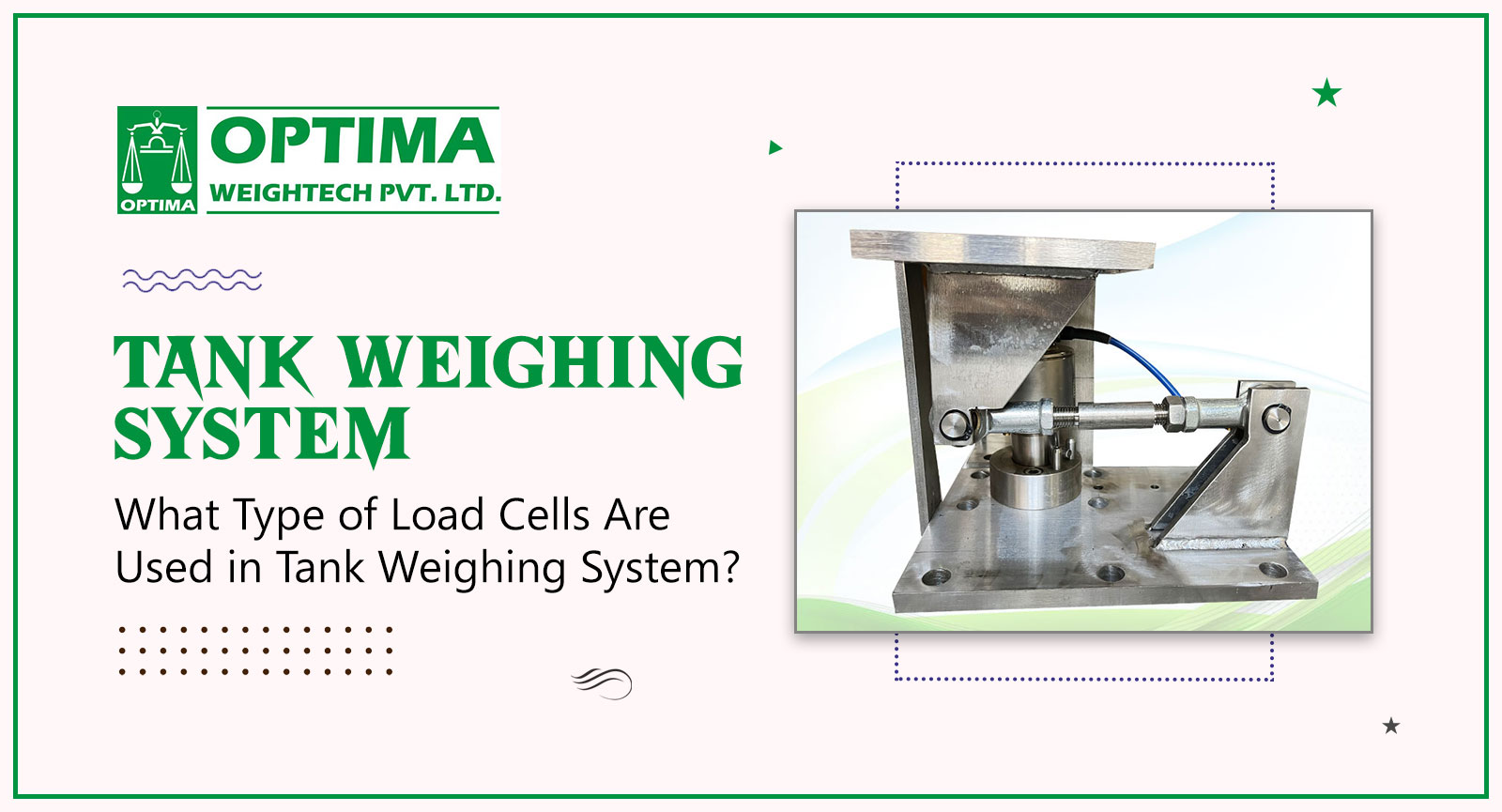

Tank weighing scales typically have load cells placed underneath the tank to detect its weight. Load cells are sensors that convert force or weight into an electrical signal. In the context of tank weighing systems, these cells are responsible for translating the weight of the tank’s contents into a readable and usable output.

There are 7 types of load cells used in tank weighing systems:

Tank Weighing Assembly Load Cell: This is the main component in the system used to accurately measure the tank’s weight and contents. It can handle heavy loads and tough environmental conditions.

Shear Beam Load Cell: This type has a part that bends under the load, and strain gauges detect the bending to provide a weight reading. They are mounted on the sides of the tank. They detect the shear force resulting from the weight of the tank’s contents, making them suitable for larger tanks.

Capacitive Load Cell: Uses changes in capacitance to measure weight. It has two plates, and as the load changes, the distance between the plates changes, giving a weight measurement.

Double-Ended Shear Beam Load Cell: Similar to shear beam load cells but with load application points at both ends, providing better load distribution and reducing errors.

S-Type Load Cell: Has an S-shaped structure and is versatile for various applications. It offers high accuracy and is easy to install, making it popular in different industries.

Compression Load Cell: Specifically designed to measure compressive forces. They are used in tanks to accurately determine the weight of contents, even in high-pressure environments. These are placed beneath the tank supports, and as the tank fills or empties, the load cells compress or deform under the applied weight.

Hydraulic Load Cells: They use hydraulic fluid to measure the force applied. As the tank fills or empties, the pressure in the hydraulic fluid changes, and this change is converted into an electrical signal. These cells are ideal for harsh environments or applications where electrical components may be vulnerable.

The Bottom Line

So, these different load cells have unique features and benefits, helping industries measure weight more efficiently. Using load cells in tanks has improved efficiency and productivity in various sectors. Optima Weightech Pvt. Ltd. is a leading brand, engaged in manufacturing and supplying load cells as well as tank weighing systems. Visit our website to learn more about our product range.